Truck exhaust tips designed for high-temperature conditions leverage materials like stainless steel, specialized coatings, optimized flow patterns, and advanced cooling mechanisms to manage intense engine heat during heavy-duty operations. Key factors ensure structural integrity, compatibility with adjacent systems (e.g., brakes), and long-term durability. Proper installation and regular maintenance are vital to prevent leaks, optimize performance, reduce noise, improve fuel efficiency, and protect vehicle components. For optimal results, seek professional installation and consistent care for your high-temperature exhaust tip tailored to your truck's needs.

In the world of trucking, an exhaust tip that can withstand high temperatures is not just a nice-to-have, but a necessity. These specialized components play a crucial role in ensuring engine performance and driver safety under extreme conditions. This article delves into the challenges posed by heat, explores key features and materials that define heat-resistant exhaust tips, and provides installation, maintenance, and longevity considerations for truck owners and mechanics alike.

- Understanding High-Temperature Challenges for Truck Exhaust Tips

- Key Features and Materials for Heat-Resistant Exhaust Tips

- Installation, Maintenance, and Longevity Considerations

Understanding High-Temperature Challenges for Truck Exhaust Tips

Truck exhaust tips are designed to handle intense heat generated by powerful engines, especially during prolonged high-speed driving or heavy loads. However, navigating extreme temperatures poses unique challenges that require specialized materials and engineering for their effective management. In harsh conditions, traditional exhaust components can struggle to withstand sustained exposure to scorching heat, which may lead to performance issues or even failure.

High-temperature resistance is crucial not only for the exhaust tip itself but also for interconnected parts like brake pads, brake rotors, and other critical components in close proximity. The intense heat from the exhaust stream can cause thermal expansion and contractional stresses, affecting adjacent brake systems over time. Therefore, designing an exhaust tip capable of withstanding high temperatures involves a delicate balance between material selection, structural integrity, and compatibility with surrounding brake components to ensure optimal performance and safety under demanding conditions.

Key Features and Materials for Heat-Resistant Exhaust Tips

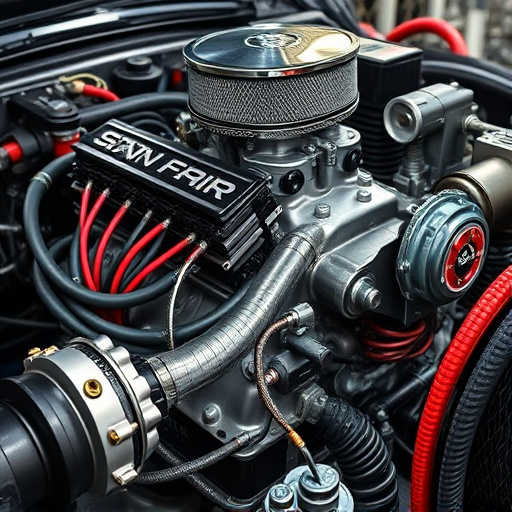

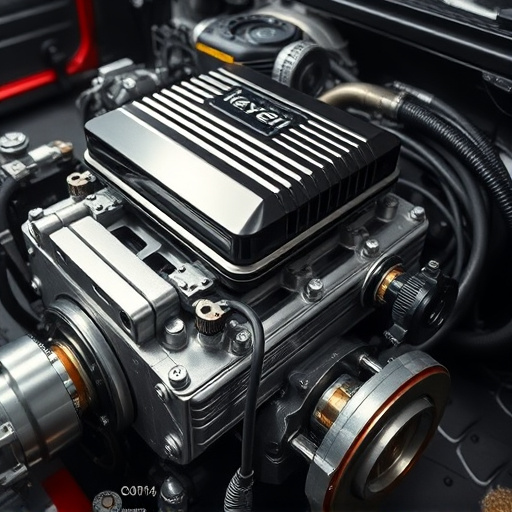

When it comes to designing an exhaust tip for trucks built to withstand high temperatures, several key features and materials play a pivotal role. First and foremost, the material used must offer exceptional heat resistance to prevent premature wear and tear. Stainless steel is a popular choice due to its strength, durability, and ability to endure extreme conditions without losing structural integrity. Additionally, specialized coatings or heat-resistant linings can further enhance the tip’s performance in high-temperature environments.

Another critical aspect is the design itself. Optimized flow patterns ensure efficient gas expulsion, reducing backpressure and minimizing the risk of overheating. Moreover, integrating advanced cooling mechanisms, such as internal water jackets or strategic vents, can significantly lower the temperature within the exhaust system, particularly in heavy-duty applications. These features, combined with high-quality materials like stainless steel and specialized coatings, make for a robust exhaust tip capable of withstanding the rigors of truck operation under extreme heat conditions, complementing other components like coilover kits and brake pads/rotors designed for such demands.

Installation, Maintenance, and Longevity Considerations

When installing an exhaust tip designed to withstand high temperatures for your truck, proper fitment is key. It’s crucial to ensure all components are securely fastened and sealed to prevent leaks that could cause damage or even safety hazards. Professional installation by a qualified mechanic is recommended to guarantee a perfect fit and optimal performance. Regular maintenance plays a significant role in extending the lifespan of your high-temperature exhaust tip. This includes routine inspections for signs of wear, tear, or damage, as well as timely replacement of any worn-out parts.

Properly maintained exhaust mufflers contribute significantly to the overall health and longevity of your truck’s exhaust system. Given that high-performance parts like these operate under intense conditions, regular cleaning and tuning can help maintain optimal efficiency. Remember, a well-maintained exhaust tip not only ensures better engine performance but also contributes to reducing noise pollution, enhancing fuel economy, and prolonging the life of your vehicle’s critical components.

When it comes to selecting an exhaust tip for your truck that can withstand high temperatures, understanding the challenges, key features, and installation best practices is crucial. By choosing heat-resistant materials and ensuring proper maintenance, you can extend the lifespan of your exhaust system, enhancing both performance and safety on the road. Remember, a well-maintained exhaust tip is not just about durability; it contributes to a smoother ride and optimal engine efficiency.